- Products / Forged Motorcycle part / Forged Engine Crankshaft

Forged Engine Crankshaft

- Category : Forged Motorcycle part

- Phone :+86-577-66859977

- Fax :+86-577-66859900

- Email :[email protected]

Crankshafts are a major motorcycle engine rotating part, which after it has been connected to the connecting rod, will carry out the conversion between reciprocating and rotational motion. It is a key engine component, and is often made of carbons teel or nodular cast iron, with crankshaft rotation acting as the driving force for both the engine and overall mechanical system.

Solutions: Forged automobile, motorcycle engine

Material: Carbon steel SAE1035, SAE 1045, CM490

Precision: ±0.01mm

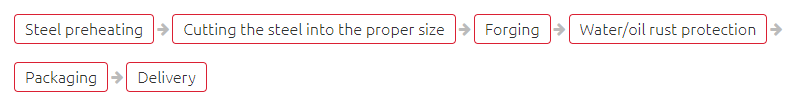

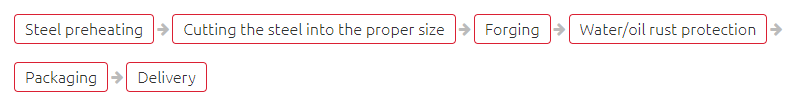

Production process

Production capability

1. We have 1600 forged engine crankshafts for customers to choose from, all of which are extremely cost effective.

2. We use a warehouse management system that follows ISO/TS16949 quality management system standards and a 6S lean management system that covers SEIRI, SEITON, SEISO, SEIKETSU, SHITSUKE, and SECURITY, thus ensuring a long product service life, as well as an easy warehouse storage and organization.

There are friction screw presses covering 630tons, 1000tons, 1600tons, and 2500tons for forgings production ranging from 1-25kg.

600-ton for forgings varying from 1-4 kg

1000-ton for forgings varying from 3-8 kg

1600-ton for forgings varying from 4-12 kg

2500-ton for forgings varying from 8-25 kg 4. We have 10 CNC processing centers, which are used for one-time processing of forgings with complex geometric shapes or with multiple processing procedures, making them more efficient and precise when compared to normal NC processing.

Solutions: Forged automobile, motorcycle engine

Material: Carbon steel SAE1035, SAE 1045, CM490

Precision: ±0.01mm

Production process

Production capability

1. We have 1600 forged engine crankshafts for customers to choose from, all of which are extremely cost effective.

2. We use a warehouse management system that follows ISO/TS16949 quality management system standards and a 6S lean management system that covers SEIRI, SEITON, SEISO, SEIKETSU, SHITSUKE, and SECURITY, thus ensuring a long product service life, as well as an easy warehouse storage and organization.

There are friction screw presses covering 630tons, 1000tons, 1600tons, and 2500tons for forgings production ranging from 1-25kg.

600-ton for forgings varying from 1-4 kg

1000-ton for forgings varying from 3-8 kg

1600-ton for forgings varying from 4-12 kg

2500-ton for forgings varying from 8-25 kg 4. We have 10 CNC processing centers, which are used for one-time processing of forgings with complex geometric shapes or with multiple processing procedures, making them more efficient and precise when compared to normal NC processing.

Raw materials mainly include carbon steel, alloy steel, stainless steel, aluminum, and copper, etc., commonly used materials are 45#, Q235, Q345, 35Mn, 65Mn, 40Cr, 35CrMo, 42CrMo, 4140, 20CrMnTi, 20CrNiMo, 304, 310, 316, 431, Al, Copper, etc.

Forging equipment has 160tons, 300 tons, 400 tons, 630 tons, 1000 tons, 1600 tons, and 2500 tons, can forge ten grams to 55 kilograms of rough forging or precision forging products.

Machining equipment has lathe, drilling machine, grinder, wire cutting, CNC and so on.

Heat treatment includes normalizing, tempering, annealing, quenching, solid solution, carburizing, etc

The surface treatment includes shot blasting, spray painting, electroplating, electrophoresis, phosphate and so on

The testing equipment includes spectrometer, metallographic analyzer, hardness meter, tensile machine, impact testing machine, fluorescent magnetic particle flaw detector, ultrasonic flaw detector, three coordinates, etc

Products are widely used in petrochemical industry, engineering machinery, auto parts, locomotive and railway parts, metallurgy, shipbuilding, military products and other fields.

Forging equipment has 160tons, 300 tons, 400 tons, 630 tons, 1000 tons, 1600 tons, and 2500 tons, can forge ten grams to 55 kilograms of rough forging or precision forging products.

Machining equipment has lathe, drilling machine, grinder, wire cutting, CNC and so on.

Heat treatment includes normalizing, tempering, annealing, quenching, solid solution, carburizing, etc

The surface treatment includes shot blasting, spray painting, electroplating, electrophoresis, phosphate and so on

The testing equipment includes spectrometer, metallographic analyzer, hardness meter, tensile machine, impact testing machine, fluorescent magnetic particle flaw detector, ultrasonic flaw detector, three coordinates, etc

Products are widely used in petrochemical industry, engineering machinery, auto parts, locomotive and railway parts, metallurgy, shipbuilding, military products and other fields.

Mold development process

The R&D team conducts CAD design, CAM, UG, SOLIDWORKS modeling work.

We use superfine die steels as the raw material, allowing them to be processed with a CNC center, ensuring that the die steel’s precision is ensured and has excellent fatigue resistance, abrasive resistance, making sure that the forgings are produced in high quality.

There are more than 2000 sets of molds here at our company. The customers can choose any of them for processing to minimize cost. We perform inventory taking, clearing and recording every week to ensure that the production proceeds as scheduled.

Our mold warehouse is managed by following the IATF16949 quality management system and “6S lean managementâ€, giving a long service life to the mold and making it convenient for use and storage.

The R&D team conducts CAD design, CAM, UG, SOLIDWORKS modeling work.

We use superfine die steels as the raw material, allowing them to be processed with a CNC center, ensuring that the die steel’s precision is ensured and has excellent fatigue resistance, abrasive resistance, making sure that the forgings are produced in high quality.

There are more than 2000 sets of molds here at our company. The customers can choose any of them for processing to minimize cost. We perform inventory taking, clearing and recording every week to ensure that the production proceeds as scheduled.

Our mold warehouse is managed by following the IATF16949 quality management system and “6S lean managementâ€, giving a long service life to the mold and making it convenient for use and storage.

Design and manufacturing

We will design and manufacture forging molds on receipt of the customer’s drawings or samples, then we will manufacture the mold by following the mold design. The molds often include forging dies, trimming dies.

Steel billet cutting and heating

Often, we will prepare the frequently used material in stock featuring material No. of 20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235, Q345, A105 etc. Then an intermediate frequency furnace will be used for heating the raw materials into certain temperature and finally putting the eating rod on the metal framework for forging.

Forging

Before metal forging process starts, the top and bottom dies shall be connected to anvil block of forging press. Then the workers will pick the metal materials and put them between the forging dies to achieve desired shape by pressing the metal materials several times with a high-speed.

Cleaning

After the forging completed, there will be unwanted burrs around the forged blanks, so removing the burrs is a necessary step. Which requires the workers to mount the trimming dies under the punching press, then pressing the forged blanks to clean burrs on the surface of the forgings.

Heat treatment

Heat treatment process helps to get the required mechanical performance and hardness of products. The heat treatment techniques cover normalizing, quenching, annealing, tempering, hardening and so on.

Shot blasting

After shot blasting process, the forgings will have a smoother and cleaner surface than it would have been. Usually the surface smoothness of the forgings is available in Ra6.3, which is even smoother than that of the lost-wax casting.

Processing

For some components, the forging process is not available in the required tolerance, under this case, processing is optional. We will conduct the product processing with different processing equipment, including milling machine, boring machine, drill press, grinding machine, numerical control machine etc.

Surface treatment

In most cases, if no specific requirements required, we will have water/oil rust protection treatment on the surface of the forgings. We can also conduct other surface treatments, including paint spraying, powder coating, electroplating, electrocoating to meet specific needs of our customers.

Final examination

We will have an inspection on the product size to ensure high quality of our products.Sometimes, we also have mechanical performance and chemical components testing on our products.

Package and delivery

In most cases, the forged components will be packaged in polyethylene bags and then being put into firm wooden boxes. We are also able to customize packages according to the customer’s needs. As we are located in Ruian forgings industrial park, we have easy access to raw materials supply, which is cost effective on the whole.

We will design and manufacture forging molds on receipt of the customer’s drawings or samples, then we will manufacture the mold by following the mold design. The molds often include forging dies, trimming dies.

Steel billet cutting and heating

Often, we will prepare the frequently used material in stock featuring material No. of 20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235, Q345, A105 etc. Then an intermediate frequency furnace will be used for heating the raw materials into certain temperature and finally putting the eating rod on the metal framework for forging.

Forging

Before metal forging process starts, the top and bottom dies shall be connected to anvil block of forging press. Then the workers will pick the metal materials and put them between the forging dies to achieve desired shape by pressing the metal materials several times with a high-speed.

Cleaning

After the forging completed, there will be unwanted burrs around the forged blanks, so removing the burrs is a necessary step. Which requires the workers to mount the trimming dies under the punching press, then pressing the forged blanks to clean burrs on the surface of the forgings.

Heat treatment

Heat treatment process helps to get the required mechanical performance and hardness of products. The heat treatment techniques cover normalizing, quenching, annealing, tempering, hardening and so on.

Shot blasting

After shot blasting process, the forgings will have a smoother and cleaner surface than it would have been. Usually the surface smoothness of the forgings is available in Ra6.3, which is even smoother than that of the lost-wax casting.

Processing

For some components, the forging process is not available in the required tolerance, under this case, processing is optional. We will conduct the product processing with different processing equipment, including milling machine, boring machine, drill press, grinding machine, numerical control machine etc.

Surface treatment

In most cases, if no specific requirements required, we will have water/oil rust protection treatment on the surface of the forgings. We can also conduct other surface treatments, including paint spraying, powder coating, electroplating, electrocoating to meet specific needs of our customers.

Final examination

We will have an inspection on the product size to ensure high quality of our products.Sometimes, we also have mechanical performance and chemical components testing on our products.

Package and delivery

In most cases, the forged components will be packaged in polyethylene bags and then being put into firm wooden boxes. We are also able to customize packages according to the customer’s needs. As we are located in Ruian forgings industrial park, we have easy access to raw materials supply, which is cost effective on the whole.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at [email protected] or use the following enquiry form. Please allow us to provide you with the best service.

Related Products

Quality is the foundation, every aspect of our activity is based on operated within strictly defined procedures, and this philosophy prevails through every department within the company.