- Home / News

-

- Saturday, 23 May 2020

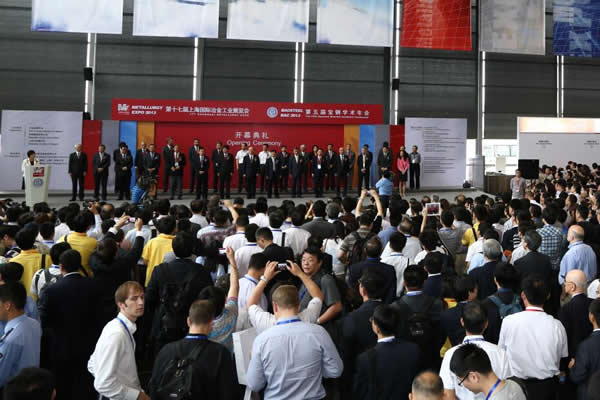

"China (Shanghai) International Forging Exhibition, China (Shanghai) International Forging Products Exhibition" was founded in 2005 and has been successfully held for 15 sessions. The exhibition covers forgings, forging flanges, rings, forging materials, forging equipment and forging accessories In other fields, it is the most professional and authoritative professional forging exhibition held in China. The scale of the exhibition has grown stronger and stronger, and it has developed from a single on-site display platform into an international stage that integrates three-dimensional display of enterprises and interactive exchanges in the industry.

-

- Saturday, 23 May 2020

The most important point of precision forging is the word precision. High-quality precision forged parts require high-quality tools and mechanics to complete. So, how can we produce high-quality precision forged parts? Today, the editor will tell you about the process of precision forging: first, cut the material into the required heating, size, forging, heat treatment, cleaning and inspection. Attention should be paid to the protection of people throughout the production process. Forging is a processing method that applies pressure to a metal blank by a forging press to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. This requires the cooperation of people and machines to produce high-quality products: microclimate environment, noise and vibration, air pollution, etc. all need us to consider.

-

- Saturday, 23 May 2020

Cast flanges and forged flanges cast flange blanks have accurate shape and size, small processing capacity, and low cost, but casting defects (porosity, cracks, inclusions, because the flange replaces the forged cross-section during quenching and cooling, the cooling rate The thickness of the cross-section of different parts is different, and the cooling rate gradually decreases from the surface. The forged cross-section is the main reason for the inconsistency of the microstructure and mechanical properties of different parts; casting flange: irregular internal structure (such as cutting parts, streamlines) Smaller); forging is not easy to rust, forging shape, forging structure is compact, better than performance; if the forging process is not suitable, the grain size of the casting will be larger or uneven. The cost of forging is higher than the casting flange. The forging can withstand more than Higher shearing force and tension of the casting. The advantage of the forging is that the internal structure is uniform, and there are no harmful defects such as pores and inclusions inside the casting.

- 1