- Home / Faq

Raw material

As the raw material constitutes the first and most important part for product quality, we have long cooperated with renowned raw materials suppliers to ensure product quality.

Every time we received the raw material, we perform a chemical components test on the material to ensure they are qualified and free from any problems. As we have a monthly 1000tons raw material stock, so raw material warehouse has been established here for better storage.

Control on the processing process

The processing operation is also a critical factor affecting product quality, so we not only have eight precision forgings production lines with the production capability varying from 300T to 4000T, as well as several pieces of production and processing equipment, which cover friction screw presses, heat treatment furnaces, shot blasting machines, forging presses, pneumatic forging machines and punching presses.

Besides, we also pay much attention to competence of employees here at our company, with all of the operators in the processing process having years of experience and we will give regular operating training and testing to these operators.

Testing equipment

We have established a specialized testing room, which has complete testing equipment covering coordinate measuring machine, tensile testing machine, gear measuring instrument, Rockwell and Brinell hardness tester. We are able to provide testing services on the customer's required products and record the examination data in the testing report and deliver it to the customer.

Introduction: Testing equipment is very important to control product quality of the forgings. The testing machines here at our company include:

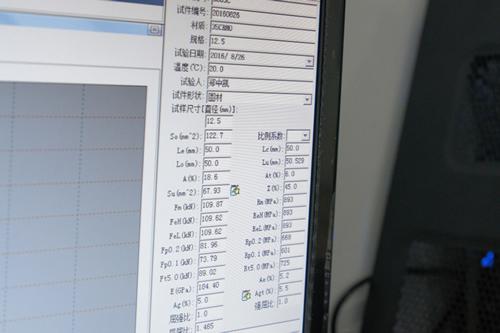

1. Tensile testing machine

Tensile testing machine is able to test mechanical performance of forgings, including tensile strength, yield strength, ductility etc.

|

|

|

| In the pressure testing, the tensile forces keep increasing. | After the pressure test, the tensile test specimen breaks after it achieves max pressure intensity. | The data from tensile test report is completely compliance with the quality standards. |

2. Coordinate measuring machine

Except for some regular Vernier calipers, we also have more precise testing equipment, such as coordinate measuring machines, with precision available within 0.0001mm.

3. Spectrometer

It is used to test whether the chemical components of raw materials are qualified and whether there are any defaults on the final forgings.

4. Rockwell and Brinell hardness tester

They are used to test whether the hardness of the forgings meet the requirements of the customers, in which, the Rockwell hardness helps to get HRC values and the Brinell for HB values.

5. Non-destructive testing

X-ray detector, non-ultrasonic flaw detector, magnetic defect detector

Third-party detection

The third party detection is to make you assured, for you might worry about our product quality even we promised having made various tests on it, so we will invite a third-party to have a quality test and after the test, a testing report on the product will be provided to the customer by the third-party institution.